NEWS

- 2022/01/13Three core factors of conveyor roller

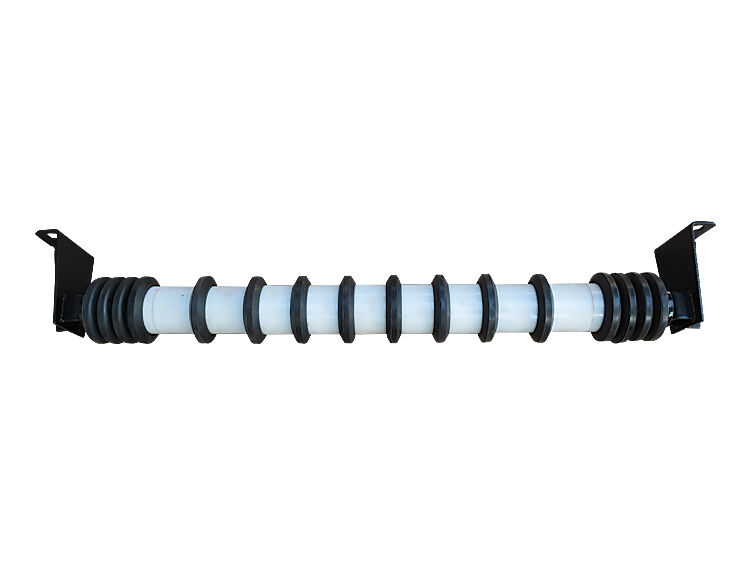

Most conveyor belts and conveyor rollers are exposed to water pollution, dust, and materials that will wear or corrode the roller tube. Therefore, conveyor belt manufacturers will introduce you to the use of rollers: ideal rollers Must have three core technologies at the same time:

1. Labyrinth sealing technology that never pollutes;

2. Roller manufacturing precision and good consistency technology;

3. Anti-corrosion and wear-resistant technology of the roller tube.

Water and dust entering the labyrinth seal is a physical principle that has not been discovered by people. As we all know, the gap of the labyrinth seal is large, and the sealing effect is not good, which is correct. However, it is a big misunderstanding that the labyrinth seal has a small gap and a large number of layers, and the sealing effect will be good. The second core technology is the manufacturing accuracy of the roller.

In China, before 1995, the roller was produced with cast iron bearing housings, with stepped holes on both ends of the tube body, and interference press-fitting; after 1995, the stamping bearing seat was gradually improved, and small stepped holes were machined at both ends of the tube body. Carbon dioxide gas Protected welding production. Neither process can guarantee that the coaxiality of the bearing positions at both ends of each roller is less than or equal to 0.05mm. Not only the rotation resistance of the roller is large, but the life of the bearing is also greatly reduced. The third core technology is the anti-corrosion and wear resistance of the roller tube.

In the iron and steel industry, the wear of coke, sintering, pellets, and steel slag is very serious. For the rollers of 4.5mm thick steel pipe, the shortest period of wear and tear is only a dozen days, and the average is about 6 months; in coal mines, According to the difference in sulfur content in the water, the most serious corrosion of steel pipe rollers is about 1mm per month, generally about 0.3mm. It is often seen in coal mines that bearings and other conveyor belt idler accessories are in good condition, and the worn and corroded idler tube body is "a mess and horrible."

- 2022/01/13The reason that affects the performance of the conveyor idler is the internal structure of the idler

1. Poor coaxiality of bearing housing:

The bearing seat used for the roller is a stamped part, and the joint with the tube is not processed, and the bearing seat is directly welded to the tube.

2. The sealing effect is not good:

Its waterproof effect is poor, and the production situation of the underground belt conveyor is dusty, and water is used to remove the dust. Therefore, the seal used for the roller must have better dustproof and waterproof effects. If water enters the roller, the bearing will be corroded, and the dust will damage the bearing, which will affect the service life of the roller.

3. Poor coaxiality of the roller shaft:

Because the cold drawn optical axis is produced due to the wear of the mold and other factors, the dimensional accuracy is unstable, and there is often the appearance of oversupport. In addition, it is easy to form twists and turns during transportation, which makes the coaxiality of the roller shaft poor. The two ends of the roller shaft are installed the gap between the bearings cannot be ensured, and then the rotation resistance of the idler roller increases, which affects the service life of the belt conveyor.

- 2022/01/13About the follow-up maintenance of Shandong mine conveyor

Yilun is a manufacturer that produces Shandong mine conveyors. In fact, many people are more concerned about follow-up maintenance after purchasing Shandong Yilun conveyors. Reasonable maintenance is also more important.

The inspection results of the mine conveyor shall be recorded in detail. In addition to the daily inspection items, check the oil level of the reducer, if necessary, add the same grade of oil; check whether the tensioning winch is flexible, whether the wire rope is worn, whether all of the pulley grooves, whether the pulley transmission is flexible, Otherwise, the stolen goods should be removed, the tension of the conveyor belt idling should be readjusted; the track of the storage belt device should be checked and cleaned. Monthly inspection: In addition to daily inspection and weekly inspection items, additional inspection of the pulley lubrication of the tensioning winch wire rope, inspection of the wear and damage of the wire rope.

Semi-annual inspection: In addition to the daily, weekly, and monthly inspections, additional inspections will be added. Add oil to all roller bearings and clean up the dirty oil on the roller; all the mine conveyor cleaner blades and the scraper of the cleaning roller that need to be replaced or exchanged must be replaced or exchanged in time; clean the reducer, change the oil, and analyze the next time Oil change cycle; check whether the medium of the fluid coupling needs to be supplemented with flame-retardant fluid (water), and all seals and bearings are worn.

The dust collection device of the mine crusher hits the mountain and transports stones or dust, which will inevitably produce pollution. Dust cleaner is a device used to separate dust from the flue gas. According to requirements such as dispersion degree. Because the dust has the same charge and repels each other, it spreads rapidly in the space of the subsequent stage to form a uniformly distributed aerosol suspension state, so that the concentration and flow rate of the subsequent bag filter are uniform. The resistance of the filter bag is significantly reduced. The former consumes more gas energy, while the latter consumes less. Check whether the resistance of the ash removal mechanism increases abnormally. Install the sleeve in the hole of the faceplate. In severe cases, it will affect the normal operation of the dust collector.

- 2022/01/13Conveyor rollers play a key role in the conveyor

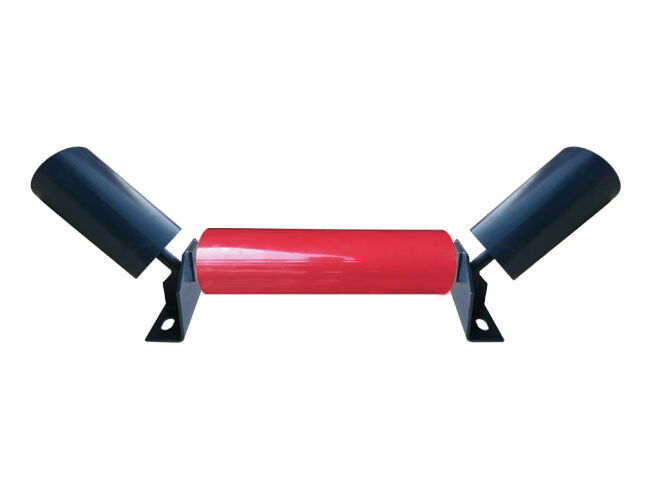

1. The impact roller is driven by a motor through a reducer, and the conveyor belt is dragged by the friction between the drive pulley and the conveyor belt. Reliable anti-skid measures must be taken for the ramp on the scaffold and the transportation road in the field, except that it should be cleaned in time. In addition to frost and snow, methods such as dusting furnace ash, sawdust, and sand can also be used to prevent slippage.

2. All technical requirements must be in accordance with the manual trough-shaped roller. The role of the roller is to support the weight of the conveyor belt and the material, reduce the friction between the conveyor belt and the roller, and affect the life of the conveyor belt that accounts for more than 25% of the total cost of the conveyor.

3. There are five other criteria for judging the quality of rollers:

1. Dustproof performance of roller

2. Waterproof performance of roller

3. The axial bearing performance of the roller

4. The impact resistance of the roller

5. The service life of the roller. The roller is an important part of the belt conveyor. There are many types and large quantities.

The heat-resistant conveyor belt is mainly based on the main performance of the heat-resistant belt’s damage and loss of conveying capacity and different heat-resistant levels. The reform of the conveyor belt has become the focus of environmental protection. It is no wonder that it is such a common one to protect the environment and save raw materials. Simple products, countless relevant professional scientific research institutes and engineering technicians engaged in production at home and abroad are committed to the research and improvement of rollers. There are hundreds of patents declared, and none of them can solve the problem of roller fragility.

The structure chain plate feeder is composed of silo interface, material guide groove, manual gate device, drive sprocket set, supporting wheel set, underframe and other parts. The components are connected by bolts, transported and assembled, and can be separated and integrated. Trough-shaped rollers are suitable for ground or underground mines. The main reasons for damage to roller bearings in coal mines are as follows: Sprinkling water and slime contaminate the roller bearings, causing the bearing resistance to increase until it jams and fails; Self-aligning brackets are installed The frictional self-aligning roller is not perpendicular to the tape at 90 degrees, but uses lateral friction to force the tape to prevent deviation. The tube wall of the roller will wear quickly, and the tape will wear very seriously. This shows that the conveyor belt support Rollers play a key role in the life of the conveyor.