1.1Production Introduction

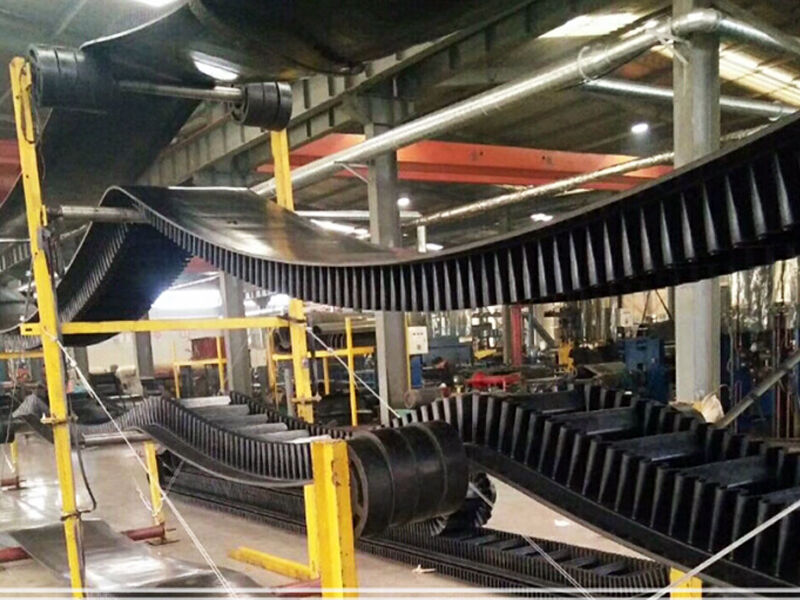

Large inclination conveyor belt is a commonly used conveying tool, which is widely used in mining, steel, coal, metallurgy and other industries. In the material transportation process, when encountering a sloping transportation environment, in order to prevent the material from rolling off, partitions are set on the conveyor belt to prevent the materials from rolling off. However, when there are more materials, the materials will accumulate on the partition and remove leakage on both sides of the partition will still cause some materials to roll off, reducing the efficiency of material transportation.

Skills requirement

1、Flame-retardant belts for mines are not allowed to have edge waves.

2、When the depth of the scar of the flame-retardant belt for mines is greater than 1mm, it should be repaired (not repaired if it is not greater than 1mm).

3、The total area of air bubbles and delamination on the covering layer of the flame-retardant belt for mines per 100 square meters shall not exceed 1600 square centimeters and should be repaired.

4、The cumulative length of the side rubber sponge on both sides of the belt or tear off the side rubber sponge shall not exceed 8% of the belt length and should be repaired.

5、For every 100 long mine-use flame-retardant tapes, there should be no more than five places with a depth of less than 1mm to press on the edge glue, and they should be repaired (not repaired if the depth is less than 1mm).

6、No steel wire rope shall be exposed on the flame-retardant belt for mines.