1.1Prodcution Introduction

Steel cord conveyor belts can be widely used in coal, mines, ports, metallurgy, electric power, chemical industries and other fields, and are suitable for conveying materials under high-strength, long-distance, and large-volume occasions.

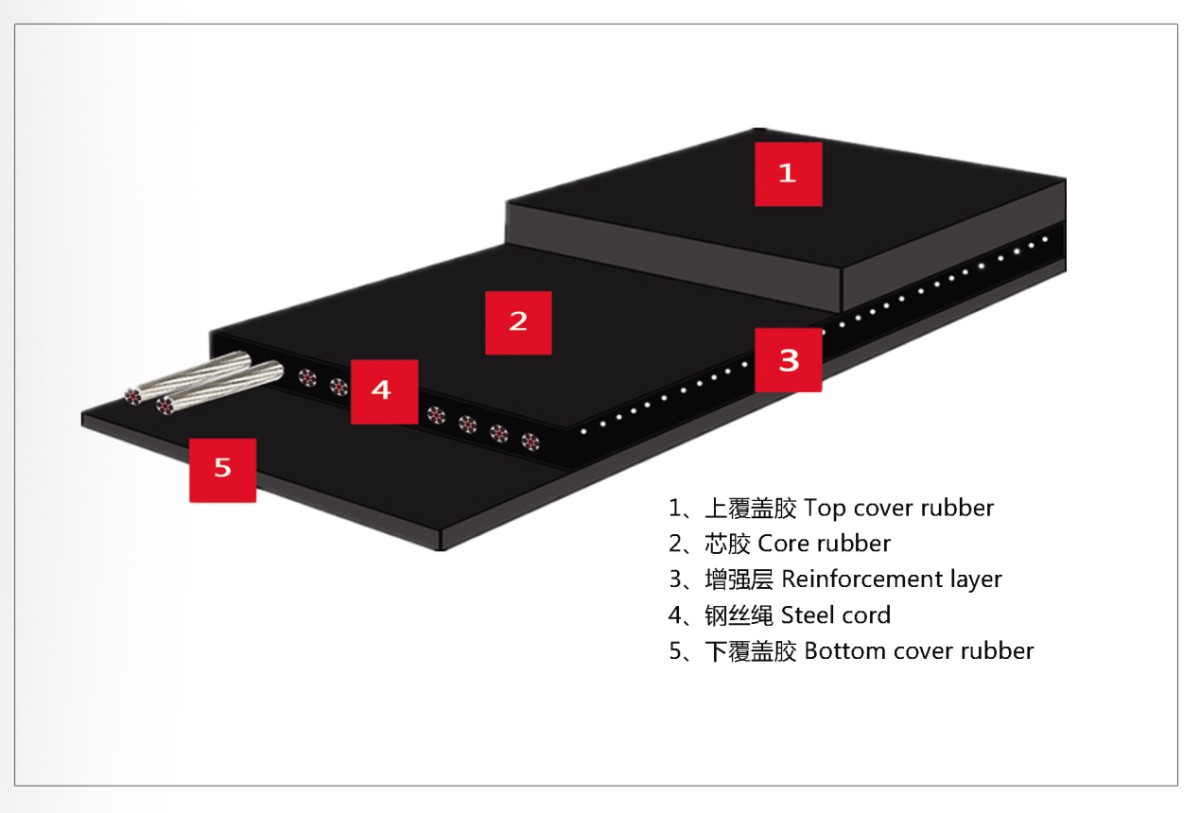

Features of ordinary structure steel cord conveyor belt:

The new structure steel wire rope is used as the tensile body, which has the advantages of high tensile strength, low elongation, good groove formation, and good flexural resistance. It is suitable for long-distance, large-capacity, and high-speed transportation of materials.

The characteristics of new structure steel wire rope infiltration:

The core rubber has enough penetrating space to enter between each strand. The rubber and steel wire rope have high bonding strength, good anti-corrosion performance, alleviating the mutual shear and twisting of the strands, and excellent dynamic fatigue resistance, which gives the product more Long service life.

Anti-tear (transversely reinforced) steel cord conveyor belt

Structure:

The new structure type steel wire rope is used as the tensile body, which is perpendicular to one or both sides of the longitudinal steel wire rope, and the steel wire rope, steel cord, fiber rope, fiber fabric and other reinforcement layers are evenly laid horizontally.

Feature:Good impact resistance and excellent tear resistance.

Embedded coil anti-tear type

Structure:

The new structure is used as the tensile body. Between the core rubber and the lower covering layer of the steel cord conveyor belt, a phase shift sensor (coil) is buried at a certain distance along the longitudinal direction.

Feature:

1、Microcomputer programming control, when the conveyor belt is detected to be torn, it will alarm and stop automatically.

2、When the running speed of the conveyor belt is abnormally reduced to the set stop speed, an alarm will be issued and the machine will stop automatically.

3、With memory, display the operating data and status of the conveyor belt.

The main technical parameters of the flame-retardant steel wire rope core conveyor belt for coal mines produced according to the MT668-2008 standard:

Varieties and implementation standards of steel cord conveyor belts

Variety:

According to the performance of the covering layer, it can be divided into: common type, flame-retardant type for coal mines, flame-retardant type for general use, cold-resistant type, wear-resistant type, heat-resistant type, acid and alkali-resistant type, oil-resistant type and other varieties.

Standard