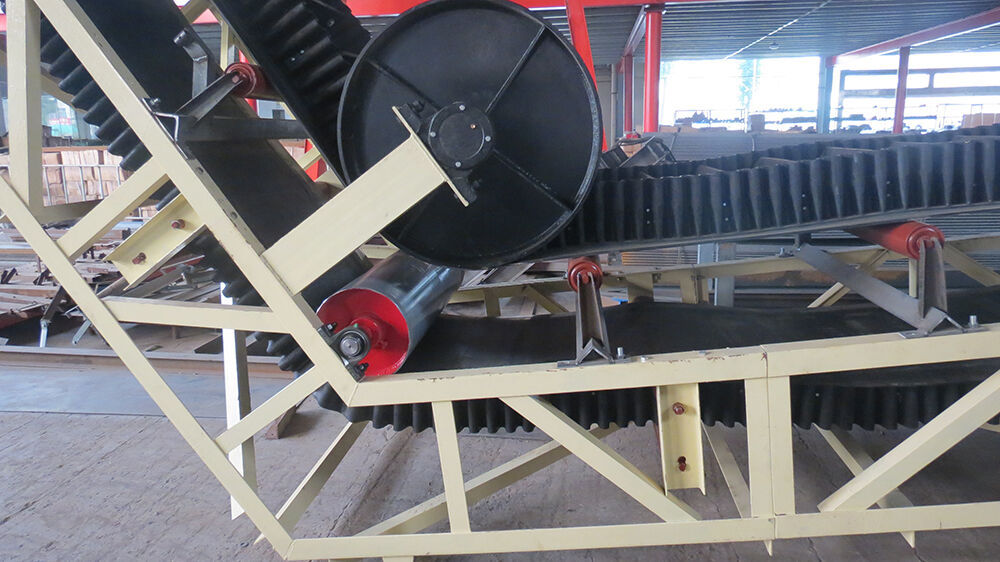

DJA, DJ, DJC type large inclination side wall belt conveyor

This series of large inclination sidewall belt conveyors are general-purpose continuous conveying equipment for bulk materials, which can be widely used in coal, food, building materials, chemical, hydropower and metallurgy and other sectors. The ambient temperature is -19℃~+40℃. Transport various bulk materials with a bulk density of 0.5-2.5t/m3. For conveying materials with special requirements, such as: high temperature, acid, alkaline, oily substances or organic solvents and other ingredients, special rib conveyor belts are required. Conveying inclination is any angle within the range of 30°~90°, and the maximum conveying material particle size is 400mm.

Features:

1. Conveying bulk materials with a large inclination angle can save a lot of equipment area and solve the conveying angle that cannot be achieved by ordinary and patterned belt conveyors.

2. The mechanized belt conveyor conveys materials, and the overall investment cost is low, which can save 20%-30% of the investment cost, and the effect is better in the concrete and coal industries.

3. Compared with ordinary conveyors, bucket elevators, and scraper conveyors, this model has superior comprehensive technical performance.

4. The conveying capacity is large, can up to 2500m3/h, and the vertical lifting height is up to 200m.

5. When conveying materials vertically, the particle size can be as large as 400mm.

6. Smooth transition from horizontal to inclined (or vertical).

7. Low energy consumption, simple structure and convenient maintenance.

8. The tape has high strength and long service life.

Main technical parameters of large inclination rib belt conveyor

(type DJA、DJ、DJC、DJF)